概述工业中的过程控制是指以温度、压力、流量、液位和成分等工艺参数作为被控变量的自动控制。就一般而言,管理中采取的控制可以在行动开始之前、进行之中或结束之后进行,称为三种控制模型。第一种称为前馈控制或预先控制,第二种称为过程控制或同期控制,第三种称为反馈控制或事后控制。

德国Sartorius Maxxis 5是一款可自由编程的过程控制器,专为各种相位、配料、填充、中型散装容器、计数和汽车地磅而设计。连通性广,可兼容所有的模拟和数字称重传感器,台秤,磅秤和更多称重方案。

The freely programmable process controller Sartorius Maxxis 5, designed for applications as diverse as Phase, Batching, Filling, IBC, Counting and Truck Weighing. Extensive connectivity options and compatibility with all analogue load cells and the digital Pendeo® load cells as well as platform scales and many more weighing solutions.

Process Controller for the automated control of weighing processes with up to four scales

最多可连接4个台秤,进行自动化控制

Wide range of opportunities for flexible integration such as option cards, housings, W&M certification and EX approvals

各种选项帮助扩展功能:W&M认证10,000 e和EX防爆认证

DAT, multilingual easy-operation interface, backup function, service reports, simulation

数字辅助技术,操作方便,具有备份,服务报告、模拟等功能

BASIC application with weighing, check and remote terminal function

With an additional license: internal alibi memory, OPC server, tilt correction

Supplied with Ethernet TCP | IP, Modbus TCP, RS232, RS485, USB, SD Card

基本版本带有称重、检重和远程终端功能,还可选择存储,OPC服务器,倾斜校正,Ethernet TCP | IP, RS232, RS485, USB, SD卡。

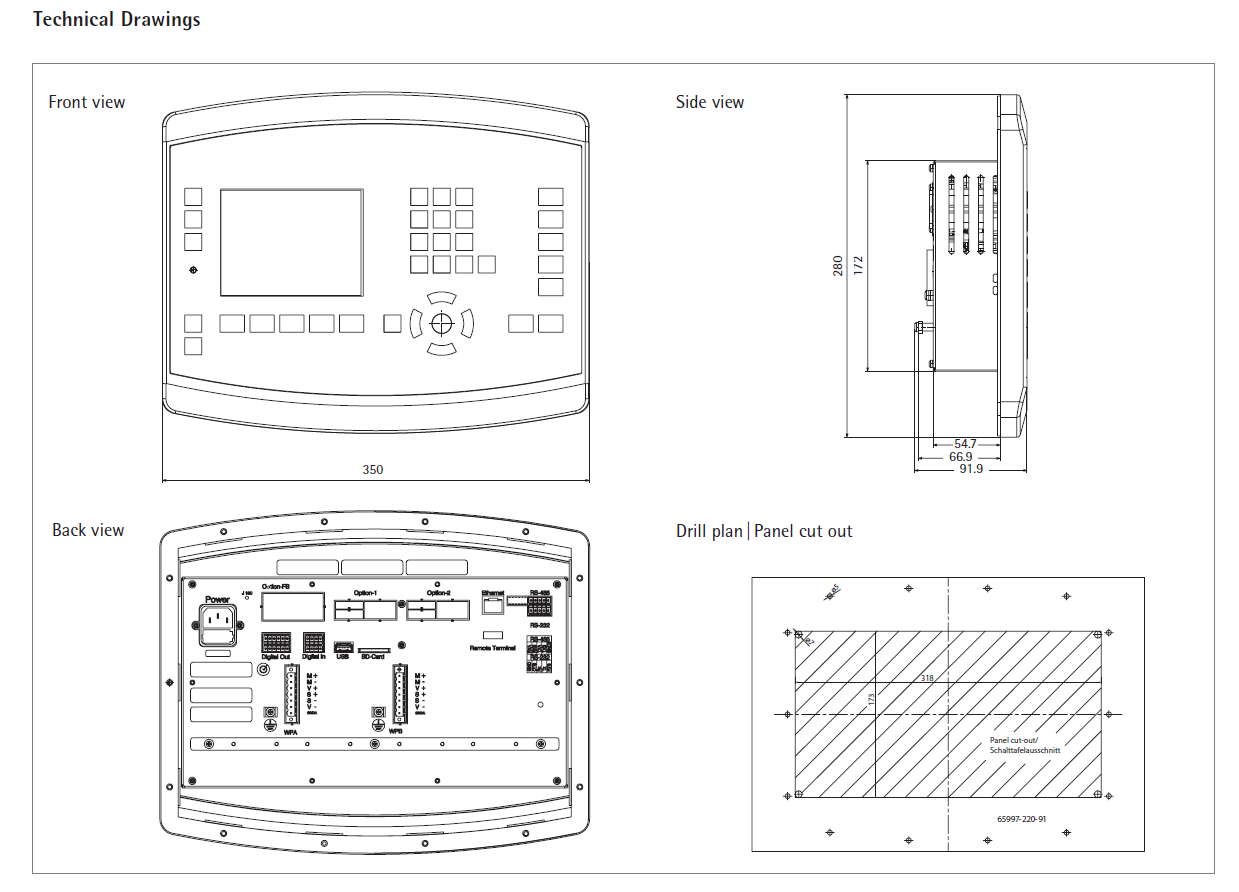

Load cell connection All strain gauge load cells; 6- or 4-wire connection Load cell supply 12V, short-circuit proof. External load cell supply possible. Minimum load impedance min. 75 Ohm e.g. 6 load cells with 650 Ohm or 4 load cells with 350 Ohm Measuring principle Measuring amplifier: Delta-Sigma converter Measuring time: min 5 ms – max. 1600 ms Digital filter for load cell 4th order (low pass), Bessel, Aperiodic or Butterworth ATEX Zone 2/22 approved (Option) Zone 2, IIC T4 / Zone 22, IIIC T80°C Ta: -10°C ... +40°C Approved for FM/CSA Class I Div.2 (Option) NI / I / 2 / ABCD / T4 Ta = -10°C to +40°C – 2015571; NIFW ANI / I, II, III / 2 / ABCD / T4 Ta = -10°C to +40°C – 2015571; NIFW 4,8 nV (appr. 7.5 Mio. div.) Usable resolution: 0.2 μV/d Measuring signal: 0 to 36mV (for 100% nominal load) Linearity < 0,003% | A | D Converter Input range Control outputs 4 relay two way contact Max. switching voltage 31 V DC | 24 V AC Max. switching current: 1 A Control Inputs Quantity: 4 opto-decoupled inputs Can be used as 'passive' or 'active' Voltage Input (active): Can be switched via a potential-free contact Input (passive): – Logic 0: 0 to 5 V DC or – open Logic 1: 10 to 28 V DC External power supply required Current: <7 mA @ 24 V <3 mA @ 12 V Power Supply 100 – 240 VAC, (+10/-15 %), 50 - 60 Hz max. 21 W/44 VA Optional: 24 VDC, (+/-10 %), max 20 W Temperature effects Zero: TK0 m < 0.05 μV/K RTI Span: TKspan < +/- 4 ppm/K Environmental conditions Temperature W&M: –10 °C to +40 °C Operation: –10 °C to +50 °C Storage: –20 °C to +70 °C Weight Net: 3 kg Shipping weight: approx. 4 kg |

订货型号

Type Description Order Number

Maxxis 5 Process Controller, incl. Ethernet TCP | IP and Modbus TCP

1 × RS232 and 1 × 485 | 422, 1 × USB, 1 × SD Card,

4 × digital input (active or passive optional) and 4 × digital outputs as relay

9405 159 00000

PR 5900/00 Maxxis 5 Process Controller with options: Panel housing (G1), A | D converter(W1), 110 | 230 V (L0),

BASIC Application (H0), Digital Input passive (DE1)

9405 159 00001

PR 5900/01 Maxxis 5 Process Controller with options: Panel housing (G1), A | D converter(W1), 24 V (L8),

BASIC Application (H0), Digital Input passive (DE1)

9405 159 00011

PR 5900/02 Maxxis 5 Process Controller with options: Table top housing (G2), Rear plate cable glands (L12),

A | D converter (W1), 110 | 230 V (L0), BASIC Application (H0), Digital Input passive (DE1),

Power cable with Euro Plug (EU)

9405 159 00021

PR 5900/03 Maxxis 5 Process Controller with options: Housing with bracket (G3), Rear plate cable glands (L12),

A | D converter(W1), 110 | 230 V (L0), BASIC Application (H0), Digital Input passive (DE1),

Power cable with Euro Plug (EU)

9405 159 00031